Factors to think about when selecting a homogenizer

Wet Samples - with some sort of liquid - best in generator system.

• Liquid allows for more cavitational breakdown.• PTFE bearings in generators work best with some sort of liquid in sample.

Dry Samples - when no liquids are present - best with blade system.

(Or custom bearings for non-liquid samples may be substituted)Sample Size

Generators are capable of homogenizing a sample size from 0.03ml to 20L.

(Larger non-viscous samples may be homogenized with deflector head attachment)

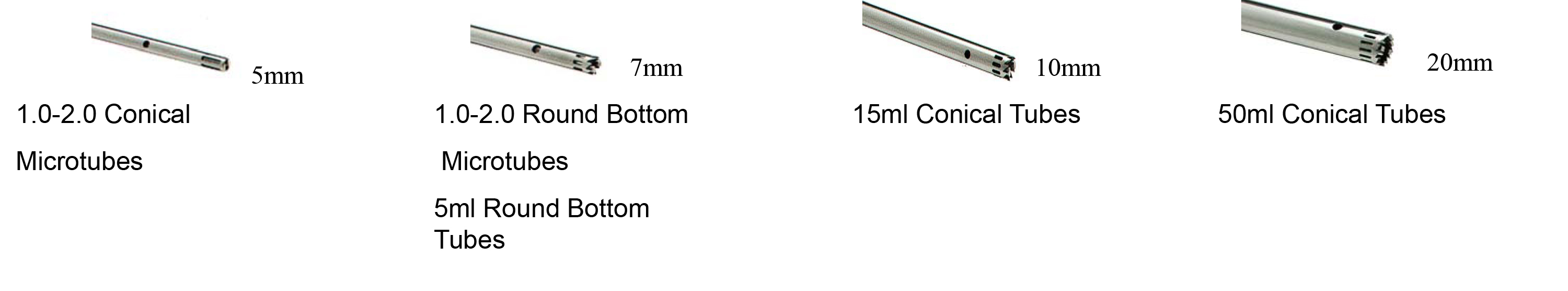

- 5mm or 7mm generators can fit into 1.5ml - 2ml eppendorf tubes.

- With a 7mm generator, the generator probe won’t touch the bottom of conical microtubes, but substance may get pulled up into generator. The generator will touch the bottom of a flat bottom microtube.

- The sample, if solid, should be no longer than half the diameter of the generator.

Generator Width

Generally, you want to homogenize and use a generator as wide as the tube you are using.

- This will allow for faster and better homogenizing because no material will "escape" from the generator.

- Keep in mind that there is some displacement of material once the generator enters the tube or container.

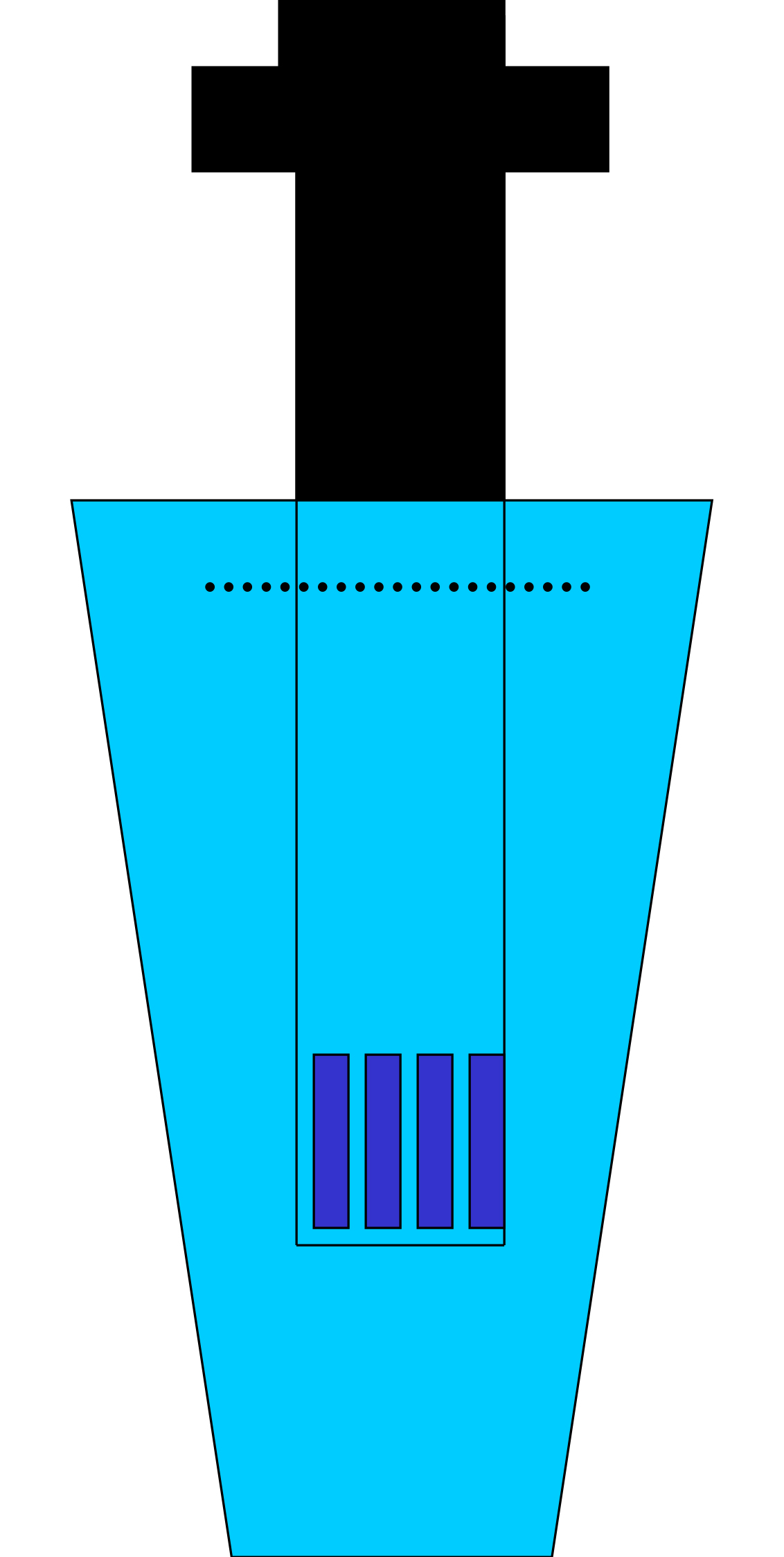

Location of the Generator Within the Sample

Place the generator off-center in the tube or container for the best results.

- This will prevent material from getting "stuck" on the walls of the tube and not being homogenized.

- Place the generator 1/3 of the sample height off of the bottom of the tube or container.

Configuration of Container& Generator Length

When using a generator 120mm or greater in length, it is important to remember that these generators have a mid-bearing. This “bearing” helps prevent bending or movement of the rotor within the tube.

This mid-bearing still needs to be kept moist during homogenizing and therefore should be kept covered by the substance being homogenized, not doing this will burn out the bearing, produce excessive amounts of heat and damage your generator. This will also cause the sample to become dingy and blackened.

If using too long of a generator for your sample size, you may start to pump air because the generator cannot recover fast enough.

Use as short a generator you can for your container/tube.

Speed and Particle Size Reduction

Always begin homogenizing at a low speed, then gradually increase speed. This allows you to remain in control of the whole process.

Peripheral speed (tip speed of the generator) which is affected by the size of the container and the size of the generator is more important then

RPM. The peripheral speed is directly proportional to the amount of cavitational breakdown. Cavitational breakdown allows for smaller particle

reduction. PRO homogenizers are capable of reducing particles to 0.01 microns when cavitational breakdown is present.

Most homogenizing can be done in 15 - 30 seconds if not you may be:

- Using the wrong size generator

- Not locating the generator properly in the container

- Too viscous of a material

To help take the guess work out of choosing a lab homogenizer, we have created a variety of PRO Homogenizing Package Kits.

These kits include everything you need to begin homogenizing

However, when a preselected package would not be ideal for you, PRO Scientific has prepared some Homogenizer Selection questions to assist you in choosing a homogenizer setup that would best suit your lab homogenizing needs.

Resources

Related Links

- Learn more about the technology behind rotor stator homogenizers

- Learn more about PRO Generator Probes

- Learn more about PRO Scientific Homogenizer Package Kits

- Contact us to arrange a demo

- Take a look at how easy it is to care for our homogenizing equipment

- Take a look at how our PRO Homogenizers compare cost wise to others on the market

- View all of our PRO Homogenizer Units

- Request a quote